Nowadays, integration is necessary for any business. It’s not enough to merely have good equipment; the machines should fit together seamlessly to avoid mistakes and save time and money. No matter which industry you’re in, integrating weighing equipment can help you keep track of inventory data, be prepared during audits, reduce waste and process inefficiencies. Proper integration also allows users to quickly share data throughout their system, which is particularly useful for international collaboration. In this post, we’ll cover how scales and balances can be integrated successfully into various processes from different industries.

Please note that you must make sure your software and Adam products are compatible. Test the implementation because, depending on the software, the scale may have to be configured in order to work.

Logistics

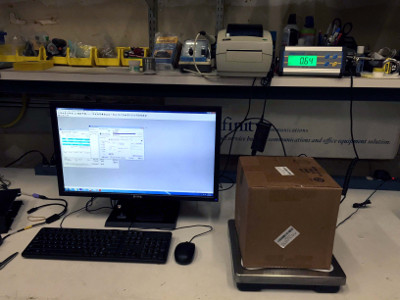

Efficiency is paramount in shipping and receiving, as parcels need to get to clients on time and within budget. Shipments can be weighed in order to estimate costs, transportation time and how they will be sent (air or ground). Weight isn’t transcribed manually most of the time, especially for high order volume. That would take too much time and comes with a high risk of mistakes. Scales like the CPWplus or the GBK can be connected to Commerce Management Systems via RS-232 or USB cables. Once the software and the scales are set up to work together, the scale connects to the software to automatically send weight data, freeing up time and maximizing efficiency of shipping departments.

On assembly lines, weight, count or checkweighing data can also be used for packaging and quality control tasks. Collecting the data also allows for proper record keeping and quick labeling. Our labeling scales and indicators feature an integrated label printer and software to edit the label’s design, text, logos, data, barcodes and more. If you need help creating labels with the software included with our label printing indicators, this guide is for you!

Health and Fitness

Digital scales like our MDW models can be connected to computers to send data to software. This can be useful for fitness enthusiasts who need something more robust than applications to collect data or athletes who are part of a health club or gym who want to track their progress.

While health records are going digital, there are a lot of rules and regulations regulating health data communication. It often is required to secure and anonymize the data. If you need medical scales to send data to software, you must check with local laws before buying and integrating weighing equipment for medical use.

Veterinary

Digital scales are very useful when taking care of animals, particularly young exotic animals who will be released in the wild, since their dietary needs and growth are very specific. In this case study, Cheetah Outreach integrated a CPWplus scale in their animal husbandry protocols in order to feed animals based on very specific food intake goals.

Laboratory

Integration is paramount in laboratory settings. Lab equipment (including balances and moisture analyzers) are often connected to LIMS systems or data collection programs such as AdamDU to process data for audits, studies and analysis. Integration is often required by laboratory guidelines to make audits easier, maintain traceability standards and to ensure the results are correct. In addition, these systems often allow users to send commands directly to balances or moisture analyzers, so users can start drying samples from their computers or set up a formulation process. The data can then be transferred to other software to be processed, graphed or stored. Everything is monitored and recorded, from calibration to testing procedures. Adam lab balances include RS-232 and USB interfaces to ensure speedy data communication and GLP-compliance.

Retail

Retail scales are often used in delis, supermarkets and shops where objects are sold by weight. They’re usually integrated to label printers or POS systems for quick service. You see that every time you weigh fruits or veggies at a shop and print a label that will be scanned by the cashier. Most scales connected to POS systems use weight to calculate prices. PLUs can be used to choose specific items (such as candy type or ice cream). Shops can even use this data to track their inventory in real time to reduce waste and anticipate demand. Some POS systems integrate easily with scales while other systems need third-party software to integrate with less known products. Retail scales can also be configured across shops or chains when integrated to ensure conformity.

How to Connect Scales and Balances

Clearly connecting scales to computers and printers has benefits. But how do you connect them? Most Adam scales include an RS-232 connector. You’ve probably seen one before: they’re these big rectangular plugs usually found in the back of computers. An RS-232 interface essentially allows for a serial transfer of data between a scale or balance and a peripheral such as a computer or printer through a cable that connects them. Electronics use binary numbers to communicate information, so the RS-232 interface transmits positive voltage for a binary “0” and negative voltage for a binary “1”. The peripheral interprets this voltage as commands it executes.

USB is replacing RS-232, and some scales and balances can now be connected to USB power sources or drives in order to power the scale or transfer results onto flash drives. USB interfaces are much smaller rectangular interfaces, usually at the front of computers and other peripherals. USB interfaces are much more complex than RS-232. They’re easier to “plug and play” in computers, but RS-232 is hardier and can cover longer distances, which is why they’re still used in electrical engineering or for products in demanding situations.

Integrating your scales and balances has many benefits, and Adam scales are designed to work well within various systems and processes. However, it’s not always a “plug and play” type of deal. We encourage you to contact us regarding your integration needs to ensure your weighing equipment gets integrated within your systems as seamlessly as possible. We also have manuals and guides available on our website to help you properly connect Adam products to computers, and our excellent customer service and technical support teams are happy to help you!